PATTREN SERIES OF CHLORINATORS AXB-1000

Automatic vacuum chlorinators of pattern series AXB-1000 refer to the class of chlorinators of ejection type, using gaseous chlorine, and are intended for dosing chlorine gas and for chlorinating drinkable waters, industrial waters and sewage.

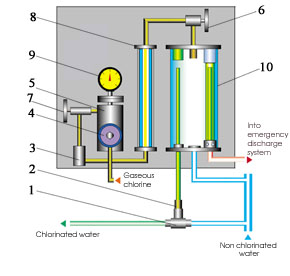

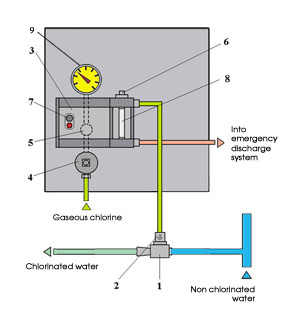

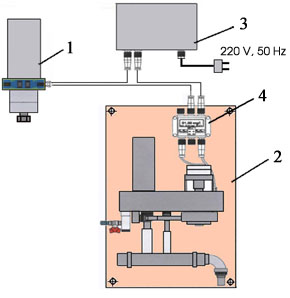

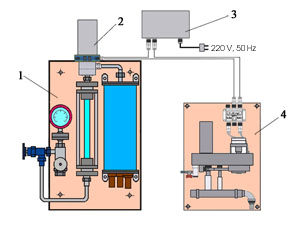

The pattern series of chlorinators AXB-1000 fulfils the demands and contains type-size series R (pic.1, marked AXB-1000/R…), as well as type-size series E (pic.2, marked AXB-1000/E…), the modifications of which cover the efficiency range in chlorine from 0,1 kg/h to 40 kg/h. Type-size series R is oriented for constructive extraction of the article's main units in order to have an access to the places of their joints for providing perfect maintainability of the device, type-size series E - for the article's maximum compactness.

|

|

| 1 - ejector; 2 - hydraulic gate; 3 - vacuum

regulator; 4 - globe valve; 5 - filter; 6, 7 - expansion valves;

8 - rotameter;9 - manometer indicator; 10 - vacuum stabilizer

(mixer).

Pic. 1. Chlorinator AXB-1000/R-SM |

1 - ejector; 2 - hydraulic valve; 3 - vacuum

regulator; 4 - globe valve; 5 - filter; 6 -expansion valve; 7

- mechanical indicator; 8 - rotameter indicator; 9 - manometer

indicator.

Pic.2. Chlorinator AXB-1000/E |

The construction of any model of the chlorinator AXB-1000 includes the following main units:

- ejector;

- rotameter or rotameter indicator of chlorine consumption;

- expansion valve for gaseous chlorine;

- locking gate for gaseous chlorine ;

- manometer indicator of chlorine pressure;

- chlorine lines;

- mechanical filter of chlorine cleaning.

Upon the customer's request the construction of the chlorinator may include the following components of the article:

- vacuum regulator (safety valve of mechanical kind);

- vacuum stabilizer - mixer (safety valve of dynamic kind);

- hydraulic valve of ejector or hydraulic gate of ejector;

- emergency alarm;

- collector, excluding mixer (collector C12.I).

Main parameters and characteristics of chlorinators AXB-1000

Assignment indexes |

Chlorinator model |

Type-size series P |

Type-size series E |

| AXB-1000/P06 |

AXB-1000/P12 |

AXB-1000/P24 |

AXB-1000/E02 |

AXB-1000/E04 |

AXB-1000/E10 |

AXB-1000/E20 |

AXB-1000/E40 |

Chlorine pressure,

kgs/cm2, no more than

|

6 |

10 |

Chlorine consumption range, kg/h |

0,3-6,0 |

1-12 |

1,5-24 |

0,1-2 |

0,2-4 |

0,5-10 |

1-20 |

2-40 |

Water pressure in water main kgs/cm2, no less

than |

2 |

Dimensions, mm, no more than:

length

width

height

|

|

|

|

|

|

|

|

|

Weight, kg, no more than: |

30 |

30 |

30 |

5 |

5 |

8 |

10 |

20 |

Dimensions of ejector, mm, no more than:

length

width

height

|

185

45

110 |

185

45

110 |

185

45

110 |

242

65

85

|

225

101

160

|

225

101

160

|

402

165

283

|

402

165

283 |

The vacuum regulator maintains vacuum in all subsequent chlorinator's units according to chlorine-gas movement when ejection is present, and shuts off chlorine-gas into these units when ejection is absent.

The vacuum stabilizer, often called a mixer in technical literature, is a component of chlorinator AXB-1000/R-SM and is assigned for preventing water penetration into chlorine-bearing units and parts of the construction when ejection is absent.

The hydraulic gate of the ejector is only used when a mixer is available for effective reduction of water quantity, feeding into the mixer from the ejector per unit time, in an emergency, connected with ejection absence.

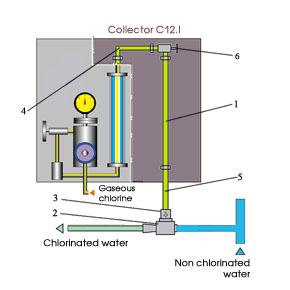

The chlorinator's ejector can be stocked with a hydraulic valve, which completely shuts off water reverse running from the ejector in an emergency. Such action of the hydraulic valve allows to avoid installing a mixer, which in this case in fact would duplicate its functions, and to connect the rotameter's outlet through the collector C12.I and ejector with the hydraulic valve (pic.3).

|

1 - retarder;

2 - ejector;

3 - hydraulic valve;

4, 5 - chlorine lines;

6 - expansion valve.

Pic. 3. Chlorinator AXB-1000/P-CL

(with collector C12.I)

|

Mentioned above main units and components of the chlorinator, included into the construction of this or that model, are mounted on the same rectangular panel, with dimensions 400x670 mm and mounting dimensions 300x570 mm accordingly.

To improve technical characteristics, chlorinators AXB-1000 according to a customer's request can be stocked with additional components, mounted separately from the chlorinator:

- a remote control system of the chlorine consumption (RCS-CCV);

- automatic regulator of the chlorine consumption (ARS-CC);

- automatic switch of cylinders with chlorine (ASCC);

- chlorine content indicator in air (CCIA);

- liquid chlorine evaporator.

RCS-CCV and ARS-CC are functionally independent devices, expanding technical capabilities of the chlorinators.

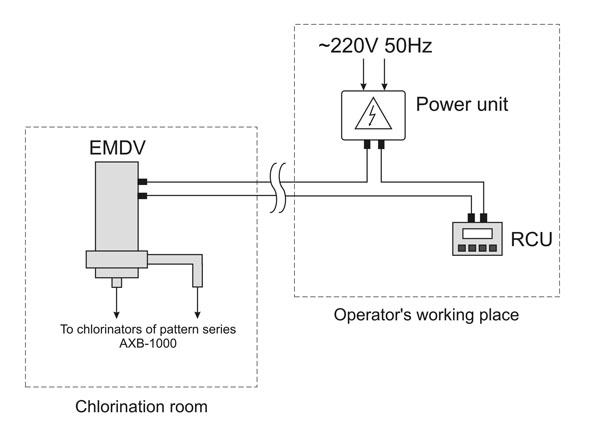

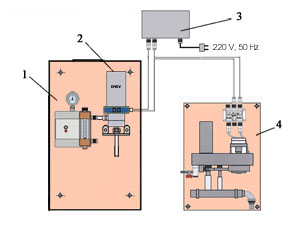

The chlorinators of the whole pattern series can be equipped with a remote control system of the chlorine consumption (RCS-CCV) (pic. 4).

Pic. 4. Remote control system of the chlorine consumption

(RCS-CCV)

This system permits to regulate chlorine supply just from the working place of an operator. So, it is not necessary for an operator to stay in the chlorination-room. RCS-CCV consists of a electro-mechanical dosing valve (EMDV), a remote control unit (RCU) and a power unit.

EMDV is assigned for dosing chlorine-gas and is adapted to the construction of the chlorinators of the whole pattern series AXB-1000. It operates as follows: depending on the control signals, supplied to it, the valve discretely increases or decreases capacity. The graphic display, located on the RCU, permits a user to check visually the chlorine consumption at the present moment. The data from other sensors, such as temperature sensor, chlorine content sensor in the air and others, can also be transferred to the remote control unit, it allows to monitor the values, transferred from these sensors, on a real time basis.

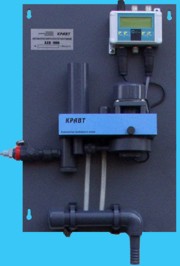

Taking into consideration the world tendencies of improving the water chlorination equipment and the market demands, SE "KRAVT" began to manufacture the automatic regulation system of the gaseous chlorine consumption in the process of chlorinating drinkable waters, industrial waters and sewage (shortly ARS-CC).

The modifications of ARS-CC provide measurement of residual chlorine in the water within the limits from 0-0,5 mg/l to 0-2 mg/l and regulation of the chlorine-gas consumption within the limits from 0,1-2 kg/h to 2-40 kg/h.

ARS-CC consists of the following units, operating as independent devices (pic. 5):

- electro-mechanical dosing valve (EMDV);

- chlorine content analyzer in the water (CCAW);

- electrical power unit.

CCAW is a sensor, operating on the basis of the amperometric method, providing continuous checking of residual chlorine in the water, which allows to change chlorine manual dosing for the automatic one. It is mounted as near as possible to the place, where the final content of residual chlorine in the water treatment process is made. This place may be both a pipe (main), and a basin.

|

1 - EMDV;

2 - CCAW;

3 - power unit;

4 - RCU.

Pic. 5. Automatic regulation system of the chlorine consumption

(ARS-CC) |

Mounting the ARS-CC with installing the EMDV onto the chlorinators AXB-1000/P and AXB-1000/E is given in pic.6, 7.

|

|

Pic. 6. Chlorinator AXB-1000/P-SM

with ARS-CC |

Pic. 7. Chlorinator AXB-1000/E with

ARS-CC |

EMDV has a high accuracy of dosing and can be controlled automatically (from CCAW), as well as manually by means of the keyboard, located on its front panel. Its reliability is provided by usage of modern chlorine resistant materials of high quality.

It is possible to transfer an electric signal, characterizing a valve's position, to the operator's console (computer). With such configuration of the chlorination plant layout, the operator's (and the personnel's) role is to check the operation of the automatic system and to maintain the units in time.

HYPOCHLORITE'S EJECTION DOSE METERS

Developing the pattern series of chlorinators AXB-1000 as to use its abilities for dosing not only gaseous chlorine, but also chlorine-containing liquids, SE "KRAVT" made and successfully tested ejection dose meters of hypochlorite with a wide range of output for hypochlorite consumption: from 0 to 0,4 m3/h (0 - 400 l/h).

As a basis, the model of chlorinator AXB-1000 with collector C12.I was taken (see pic.3), and this modification of the chlorinator was called "Chlorinator AXB-1000/R000-CL-GC". Besides in the abbreviation "R000" instead of "000" peak productivity of hypochlorite consumption in "l/h" is written, it corresponds to the client's request. In fact, using such dose meters permits to avoid dosing pumps.

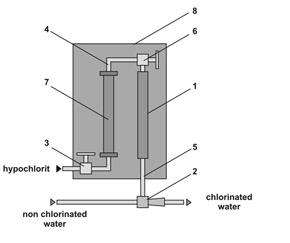

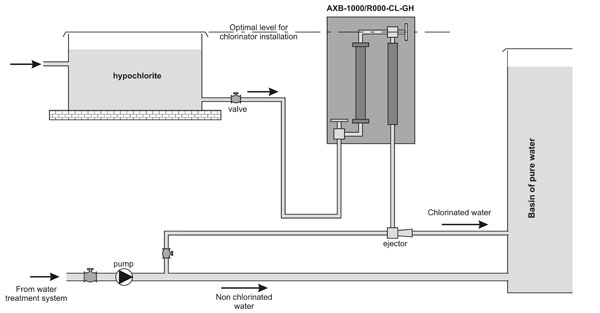

Schematically the construction of such chlorinator is represented in pic.8.

|

1-retarder;

2-ejector;

3- globe valve;

4,5-pipelines;

6-expansion valve;

7-rotameter;

8-panel.

Pic. 8. Chlorinator AXB-1000/P000-CL-GC |

It operates like the previous models. The water flow, going through ejector 2, makes suction effect, and hypochlorite under its action (i.e. due to formed vacuum) is sucked in globe valve 3, rotameter 7, pipeline 4 with expansion valve 6 and further along retarder 1 and pipeline 5 ejects into water, making the flow of chlorinated water at the ejector's outlet. Taking into consideration this action principle, let's call a chlorinator an ejection dose meter.

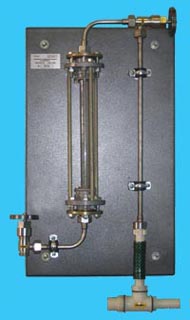

In photo 3 you can see the appearance of chlorinator AXB-1000/P000-CL-GC. Its construction consists of the same units and parts as chlorinator AXB-1000/P-GC does (see pic.3 and photo 4). Moreover, its mounting and connecting dimensions completely correspond to their values in chlorinators AXB-1000 and LONII-100, i.e. their mounting is not difficult.

In pic.9 you can see a model diagram of including the ejection dose meter-chlorinator AXB-1000/P000-CL-GC into the system of water disinfection with hypochlorite. Hypochlorite is supplied into the chlorinator from the impounding basin by gravity. To prevent ejection losses and productivity reduction for hypochlorite consumption, it is preferable to install the chlorinator not higher than the point, where hypochlorite goes out of this basin. On the diagram the optimum level of matching the basin's position (point where hypochlorite goes out) with the elements of the chlorinator's construction is shown. There is a similar diagram for swimming pools, in some cases supply of non chlorinated water from the main to the basin of disinfected water or swimming pool may be not available.

Pic. 9. Model diagram of including the ejection dose meter-chlorinator AXB-1000/P000-CL-GC into the system of water disinfection with hypochlorite

The system operates steadily in the wide range of water pressure difference at the inlet and outlet of the ejector: from 1,5 kgs/cm2 to 7 kgs/cm2 (0,15 - 0,7 MPa). Moreover, since 2 kgs/cm2 (0,2 MPa), the productivity of hypochlorite consumption increases insignificantly. That's why the system's operation is the most effective when the pressure difference at the ejector is about 2 - 3 kgs/cm2 (0,2 - 0,3 MPa).

The chlorinators AXB-1000/R000-CL-GC may also be stocked with RCS-CC or ARS-CC; or only with EMDV with a power unit.

SE "KRAVT" performs contract supervision, as well as warranty service and permanent service of the manufactured equipment, its content and volume are agreed upon with the customer.

High quality of the products, achieved by SE "KRAVT", and popular price, execution and delivery of the orders in good time, considering the speciality of the customer's demands, continuous improvement of the technologies, kindness of the personnel always attract our customers. We suggest you cooperating and making a contract for the product delivery.

PHOTOS OF BASIC ARTICLES

1. Chlorinator AXB-1000/R-SM

(master set) |

2. Chlorinator AXB-1000/R-SM (complete set with expansion)

|

3. Chlorinator AXB-1000/R-CL-GH

|

4. Chlorinator AXB-1000/R-CL

|

5. Chlorinator AXB-1000/E |

6. Automatic cylinders' switch ASCC-01

|

7. Chlorine content analyzer in air CCIA

|

8. Chlorinator AXB-1000/E with EMDV |

9. Chlorinator AXB-1000/R-SM with EMDV

|

|

10. Chlorine content analyzer in water (CCAW)

|

|

DESIGNING AND MOUNTING AUTOMATIC CONTROL AND INSPECTION SYSTEMS

Application of modern technologies and equipment, developed and used by SE "KRAVT", together with computer techniques allowed to create the automatic control and inspection system (ACIS) of operation of the main facilities of a water station (water intake), such as: a pump station; a water treatment plant, including filters, a chlorine station, hydraulic generators, compressors and a pump station; basins of pure water and others.

In this system the computer display of the operator's console provides animated illustration of real-time processing of all mentioned above units, showing the actual values of the checked parameters.

ACIS keeps automatically preset parameters (set points) of the units' functioning and also provides automatic turning on and off the actuators from the computer display. For these purposes it is stocked with the corresponding modern devices, successfully functioning at some facilities, covered by ACIS. Execution of these functions is also provided by GSM-communication, which permits a duty operator to fulfill his obligations effectively, and besides, it is possible, if necessary, for other authorized officials and specialists, independently on their location, to control the separate facilities and the whole water intake themselves.

Introduction of ACIS increases significantly the quality of functioning of such technological facilities, as a water treatment plant, and helps make efficient decisions about its operation optimization on the basis of on-line information about the current condition of every facility.

SE "KRAVT" makes contracts for designing ACIS, their complete setting, mounting and commissioning, warranty and permanent service.

|